A Quick Guide to Fashion Production

The longer I work in fashion production, the more I see your need to understand “How does this work"?”

Turning Designs into Final Products

Your vision of success, which includes the success of the final products in your shop, be it online, in a boutique, or down a runway, probably does not include fabric delays, incorrect samples, quality control issues, or the endless invoices that roll in during production.

Fashion production is an intricate process of transforming creative ideas into tangible products. The process is detailed and can feel complicated when you are just starting out.

However, as much as apparel production has confusingly interrelated processes, understanding this journey to best of your ability will streamline your operations, ensure quality, help achieve business goals.

And most importantly, in my opinion at least, is that the comprehension around these necessary steps will help you manage your expectations.

FOLLOW ALONG WITH THIS FREE FASHION CREATOR CHECKLIST

Included on this checklist is everything needed for pre-production, production and post production to create your fashion brand, brick by brick.

Here is a comprehensive guide so you can navigate the production process effectively.

1. Concept Development

Every great product starts with a concept. We know this.

This stage involves,

Design Creation: Sketches, mood boards, or digital renderings.

Material Selection: Identifying fabrics, trims, and other raw materials.

Technical Specifications: Creating detailed tech packs, including measurements, construction details, and fabric requirements.

2. Sourcing

Sourcing involves finding the right suppliers and manufacturers for your designs, to align with your ethics AND your brand values. This is relationship building, matchmaking, and requires a lot of reaching out and research. Consider,

Fabrics and Materials: Sustainable and high-quality options are increasingly valued.

Manufacturers: Look for partners specialising in your product type (e.g., activewear, denim, etc.).

Certifications: Ensure suppliers adhere to ethical and environmental standards.

3. Prototyping and Sampling

This is easily my favourite part of the process. Taking the flat, 2D information that is in a tech pack, and turning it into a tangible product that eventually guides the brand into the direction of their final vision is like stepping inside of the fashion designer’s intuitive space, their subconscious.

Prototypes and samples are essential for refining designs:

Initial Prototypes: Basic versions to test fit and design.

Fit Samples: Adjust sizing and construction details.

Sales Samples: High-quality samples for buyer showcases or marketing.

4. Production Planning

By this I mean the planning of the bulk production. This ensures efficient production and timely delivery:

Production Quantities: Decide on order volumes. The overall MOQs (Minimum Order Quantities) are decided back at Sourcing in step two. But once you have the approved sample in the third step, you then know your fabric consumption and overall number of units/style you will end up with.

Lead Times: Understand supplier timelines. By now, you will be ready to go into bulk production, and the factory can confirm how long they will need to deliver the final products.

Costing: Calculate total production costs, including materials, labor, and shipping. During sampling, the costs will be estimates. After the approved sample, you will have a firm cost/unit which will then be applied to the bulk production.

5. Bulk Production

Once samples are approved, the bulk production process begins:

Cutting: Fabrics are cut according to patterns.

Sewing and Assembly: Garments are stitched together.

Quality Control: Inspect products for defects or inconsistencies.

6. Finishing and Packaging

After assembly, products are prepared for market:

Finishing: Includes pressing, embellishments, and final touches.

Packaging: Branded tags, labels, and eco-friendly packaging materials.

7. Shipping and Distribution

Logistics play a key role in delivering products:

Shipping Options: Air, sea, or ground, depending on timelines and costs.

Customs and Duties: Ensure compliance with regulations.

Inventory Management: Plan storage and distribution.

8. Post-Production Review

Evaluate the production cycle for future improvements:

Supplier Feedback: Discuss successes and areas for improvement.

Internal Analysis: Assess timelines, costs, and product quality.

Customer Feedback: Use reviews to refine future collections.

There is a knowledge gap between start up fashion brands and the processes in production.

Book yourself in for an hour consulting call, so we can review,

Where you currently are at.

What you are planning to produce.

How you can get to a final product.

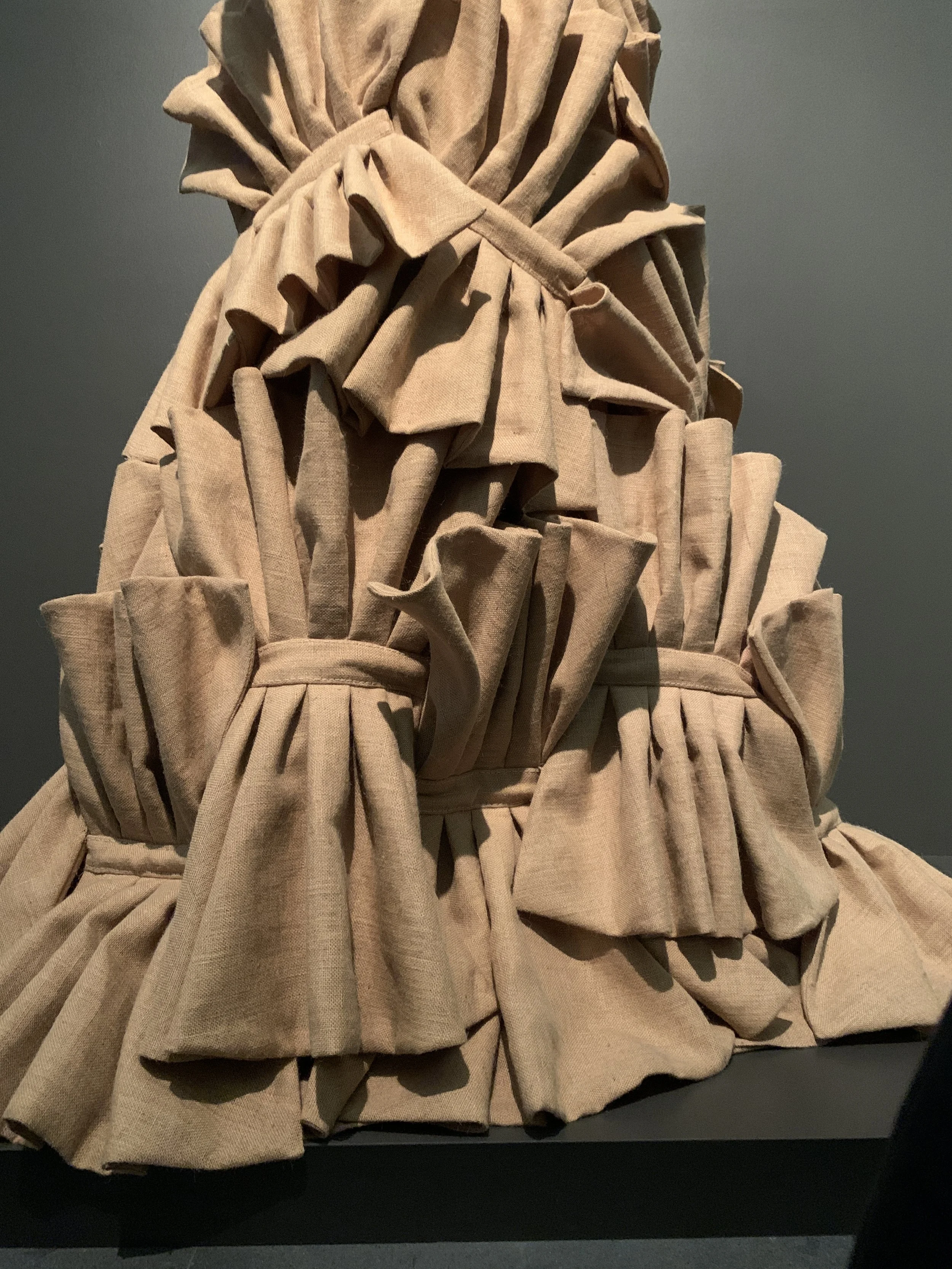

Jute dress design by Michelle Francine Ngomo // image ©Franky Dune taken at Mudec Milan

Key Tips for a Successful Production Process

Clear Communication: Maintain open lines with everyone involved in your production process, suppliers, manufacturers, production managers.

Documentation: Keep thorough records of every stage.

Quality Assurance: Prioritise consistent standards.

Sustainability: Embrace eco-friendly practices for materials and processes.

By mastering the intricacies of fashion production, brands can effectively create high-quality products that truly connect with their target audience on both aesthetic, ethics and values.

save for later!